From: ShellyDalg@aol.com

To: personal_submersibles@psubs.org

Sent: Tue, Mar 9, 2010 12:37 pm

Subject: Re: [PSUBS-MAILIST] MBT Vents

.........."They're not stainless, and they're ported way too

small, so it takes several minutes to vent the MBTs. "...........

small, so it takes several minutes to vent the MBTs. "...........

Hi Alec. I've always thought Snoopy was one of the best psubs I've seen.

On your vents,what size is used now ? How long does it take to vent the tank completely ?

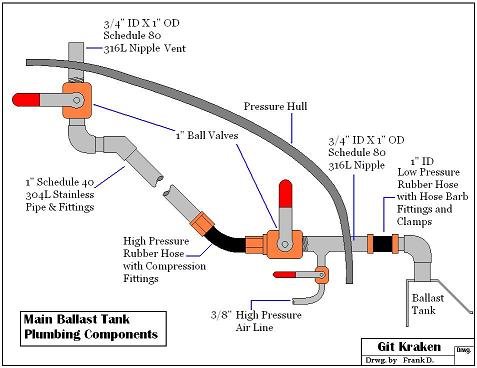

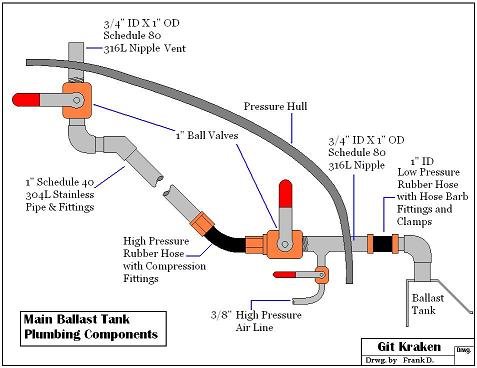

I am using 3/4 inch schedule 80 316L nipples for thru-hulls because they fit 1" valves. The interior piping is schedule 40 X 1". Bigger is better but a larger thru-hull means bigger valves and piping, and I'm curious how long it will take to flood. Here's a little sketch.

The holes in the bottom of the ballast tanks are 2 each at 2-1/2" diameter.

Frank D.