Hi Frank,

Thanks for the kudos. If

you saw Snoopy now mid refit you'd be shocked. She looks like an

absolute wreck, but hopefully in another six weeks or so will begin to come

together again.

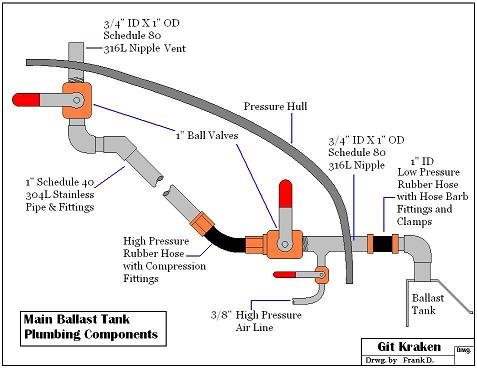

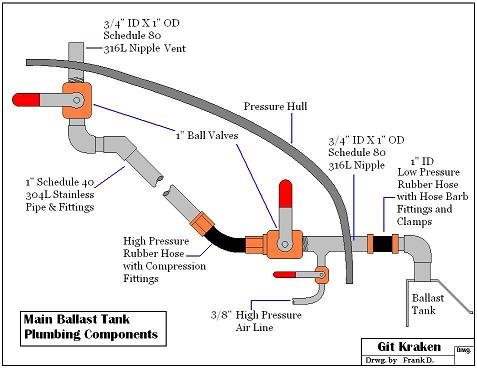

I like your drawing, but

aren't too convinced about the layout. There sure are a lot of pipe joints

inside that cabin. They are all potential little irritants, as after a

while they invariably begin to drip, especially if NPT instead of

Swagelok. The rubber hose with a compression fitting I'd be particularly

concerned about. When you open those valves at depth, the pressure

differential would be about 500 psi if this is say a 250 foot boat.

Would you subject a rubber hose in a compression fitting to that sort of

pressure? If it were me I'd put the whole lot outside with only a

valve stem coming through the hull. I

particularly liked Phil's configuration, in which a single valve does the job of

all three valves in your diagram. But if it does all need to go inside,

I'd recommend Swagelok throughout. They don't need to be 1"

although that would be nice. Get Swagelok fittings on eBay. I got myself

some shoe boxes of assorted Swagelok fittings years ago that were priced by the

pound, and I'm still using them. Visualize a big jar of nuts or bolts,

except full of Swagelok stuff. When in large assortments like that, they fetch a

tiny fraction of the new price.

But to your questions...

Snoopy's currently has 3/4" valves, meaning that's the NPT thread on them,

but they are not "fully ported". That means that inside the valve, the opening

is smaller than the input or output thread. In this case, the inside is only

1/4". I haven't timed the venting, but my guess is it's probably about 2

minutes. I get impatient with it, particularly when watching a dive on video

where the viewer has an attention span of a few seconds. I have to edit out 90%

of dive scenes.

thanks,

Alec

The contents of this e-mail are intended for the named addressee only. It contains information that may be confidential. Unless you are the named addressee or an authorized designee, you may not copy or use it, or disclose it to anyone else. If you received it in error please notify us immediately and then destroy it.

From: owner-personal_submersibles@psubs.org

[mailto:owner-personal_submersibles@psubs.org] On Behalf Of

ShellyDalg@aol.com

Sent: Tuesday, March 09, 2010 12:38 PM

To: personal_submersibles@psubs.org

Subject: Re: [PSUBS-MAILIST] MBT Vents

Sent: Tuesday, March 09, 2010 12:38 PM

To: personal_submersibles@psubs.org

Subject: Re: [PSUBS-MAILIST] MBT Vents

.........."They're not stainless, and they're ported way too

small, so it takes several minutes to vent the MBTs. "...........

small, so it takes several minutes to vent the MBTs. "...........

Hi Alec. I've always thought Snoopy was one of the best psubs I've

seen.

On your vents,what size is used now ? How long does it take to vent the

tank completely ?

I am using 3/4 inch schedule 80 316L nipples for thru-hulls because they

fit 1" valves. The interior piping is schedule 40 X 1". Bigger is better but a

larger thru-hull means bigger valves and piping, and I'm curious how long it

will take to flood. Here's a little sketch.

The holes in the bottom of the ballast tanks are 2 each at 2-1/2" diameter.

Frank D.